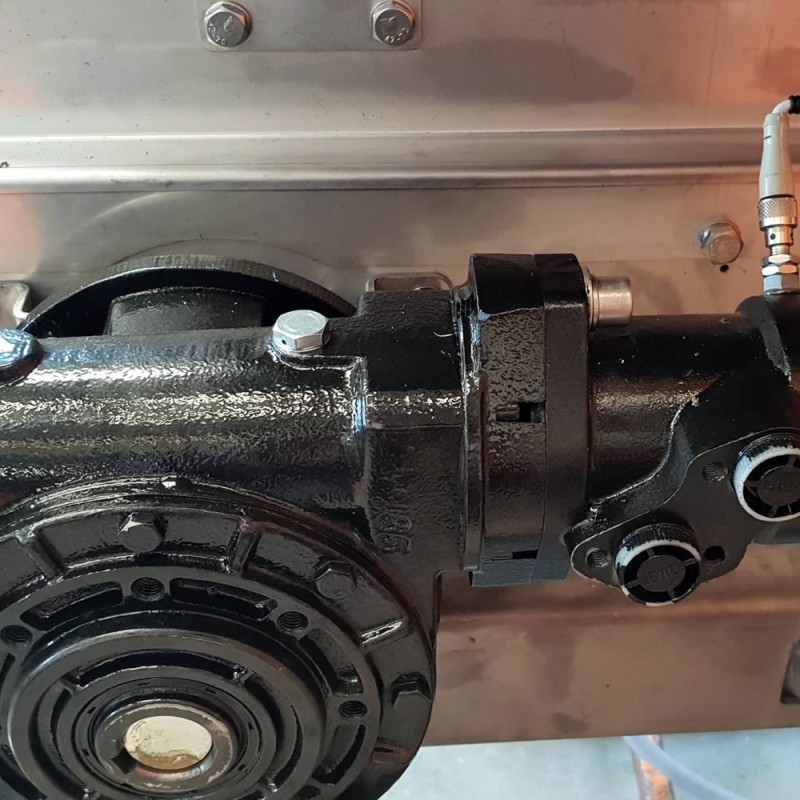

Our SPR 400 hydraulic salt spreader for trucks is powered by a specially constructed system on the transport vehicle or, alternatively, by means of a hydraulic system driven by an auxiliary motor incorporated into the spreader.

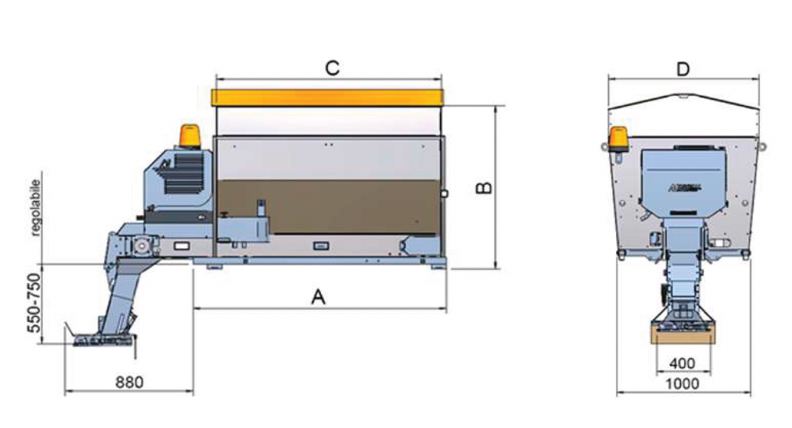

The SPR 400 salt spreader for trucks is available in versions SPR 400/500, SPR 400/750, SPR 400/1050, SPR 400/1500, SPR 400/1500 L and SPR 400/2000 L, which vary in size and load capacity.

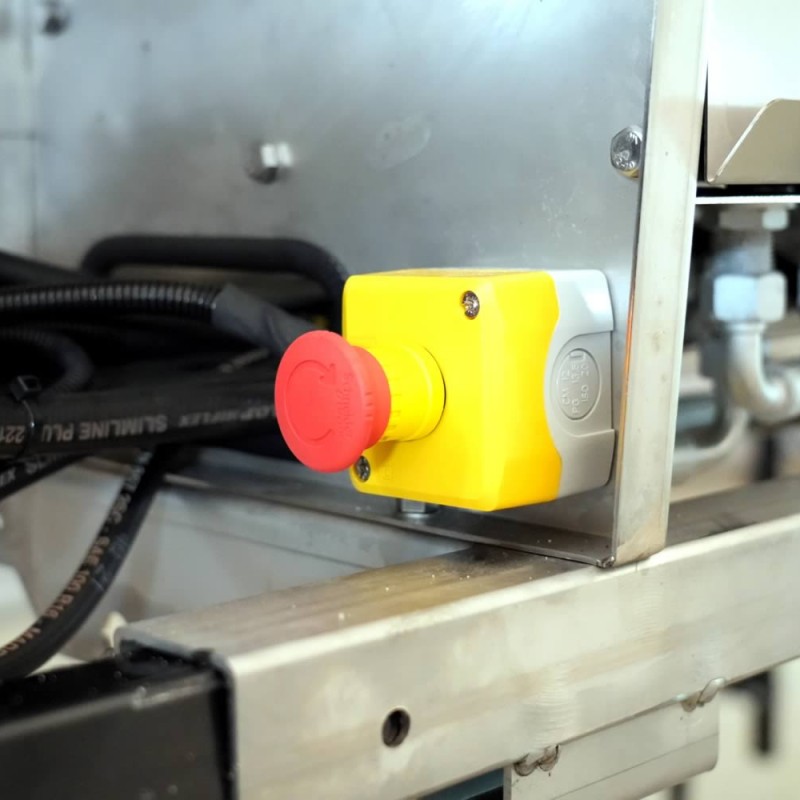

Equipped with a screen, hydraulic system ready for connection to the existing hydraulic sources on the vehicle, IP 55/65 12-volt electrical system, flashing light and rear work light, and 2-core cable for connection to the vehicle battery, the SPR 400 salt spreader for trucks also includes a push-button panel complete with all functions to control and regulate spreading.

The hopper paintwork is in Ral 2011.

The basic version of the SPR 400 salt spreader for trucks is fully equipped, including:

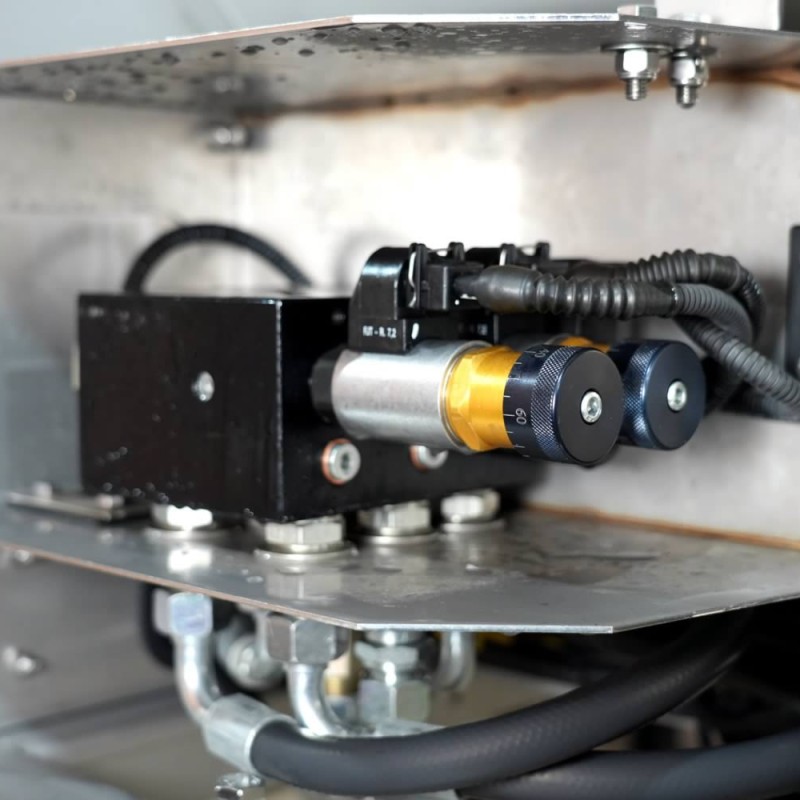

- ECO-TRONIC electronic push-button panels for spreading control (Industry 4.0)

- ECOMATIC GPS electronic push-button panels for spreading control

- Spreading system by means of a stainless steel honeycomb chain driven by 5 gears, in AISI 316 stainless steel, 375 mm wide

- Red work light

- Flashing LED light

- Lifting and securing eyebolts (no. 4 in the corners of the hopper)

- Screening grid inside hopper

- Proportional hydraulic block with option for MANUAL operation (emergency)

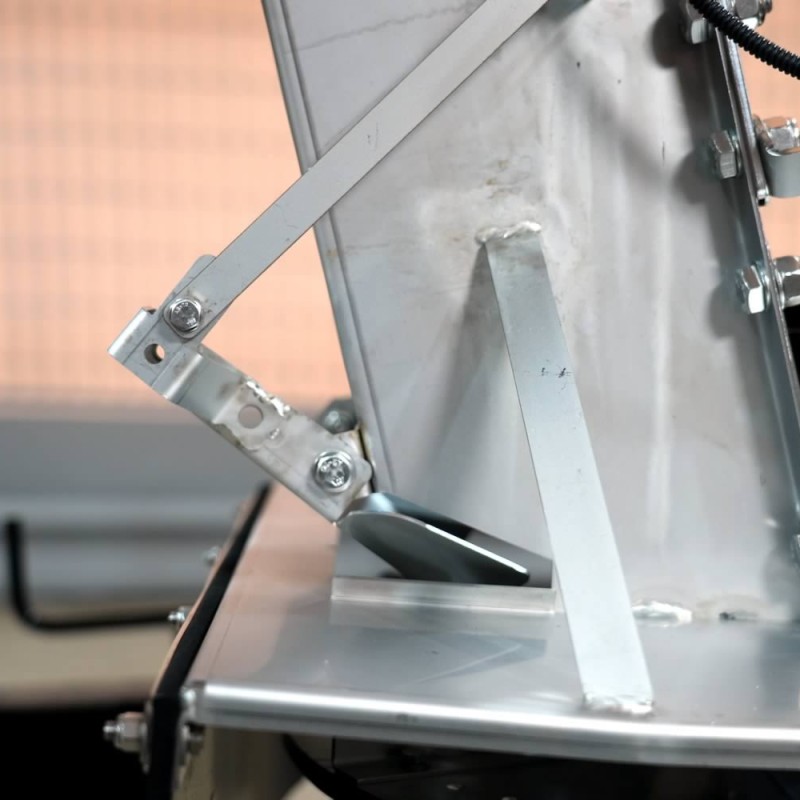

- Safety micro-switch on spinner chute

- Height-adjustable spinner chute

- Manual spreading asymmetry adjustment

- Spinner disc Ø 600 mm with no. 8 interchangeable and adjustable vanes

- Encoder on hydraulic motor to maintain spreading precision

- Emergency button in the rear

The following optionals are also available:

- Petrol auxiliary engine (12V) with independent hydraulic system

- Diesel auxiliary engine (12V/24V) with independent hydraulic system

- GPS and tachometer module for ECOMATIC WKF push-button panel for automatic spreading depending on vehicle speed

- Tarpaulin in PVC for versions SPR-400/1500 L and SPR-400/2000 L to cover the hopper

- Mandatory 50x50 “keep left” rear road sign

- Asymmetric spreading kit with push-button panel control to correct the spreading pattern

- Salt sensor with alarm LED on push-button panel to inform operator of salt shortage in hopper or of any malfunctions

- External vibrator operated by push-button panel to facilitate the removal of salt from the walls of the salt spreader

- Parking feet manually operated with crank for assembly/removal of salt spreader from the loading bed of the truck

- Vehicle fastening kit (chains and tensioners or ratchet straps)

- Dual crusher shaft kit to break up any blocks of salt before the hopper outlet

- Stainless steel ladder for hopper inspection

We focus on adapting our products to your vehicle, reducing the need for maintenance and customising our services.

For special requirements, our equipment can be adapted to suit your needs. Contact us for a personalised quote.

Add a review

Our Contacts

SNOW EQUIPMENT

SHOP

Via dell'Industria, 34

41013 Piumazzo di Castelfranco Emilia (Modena),

Italy

+39059.931483

info@snowequipmentshop.com

Contact Us

Contact Us For Any Questions

English

English

Salt spreaders and spreaders

Salt spreaders and spreaders

Snow ploughs and V-shaped snow ploughs

Snow ploughs and V-shaped snow ploughs

Street cleaning

Street cleaning

Spare parts

Spare parts

Fire modules

Fire modules

Customer questions & answers

Customer reviews

5.00 out of 5